Motor speed can be based on an analog signal, transducer, temperature, potentiometer or Modbus. East set-up using Navigator handheld programmer or Modbus port. Constant pressure or flow can be maintained with PID Plus programming. VFDs are used in applications ranging from small appliances to large compressors.

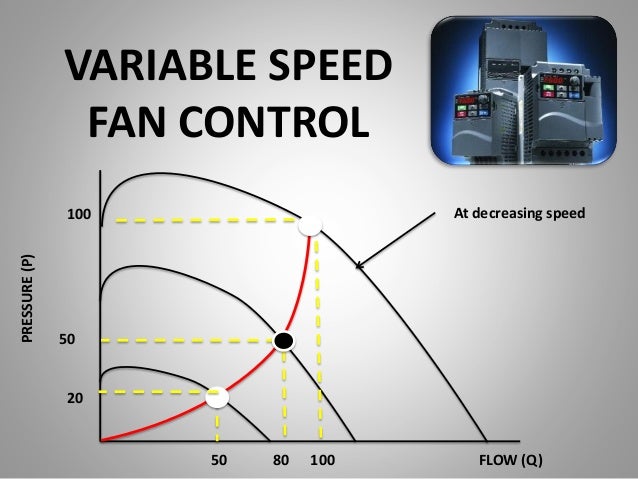

Most fans and water pumps are selected according to its full loads working status, but in practice they are not working at the full load state in most of the time.

By precisely matching fan motor speeds to the required heat rejection, VFDs can significantly reduce en-.

The ACvariable speed drive has been designed to provide users with exce.

An example is the MicroMetl Modulating Power Exhaust. In our Scrubber system WE NEED TO CONTROL THE SUCTION FAN( CENTRIFUGAL) SPEED BY OUR 4-MA FROM THE MASS FLOW METER USING – VARIABLE FREQUENCY DRIVE ( VFD ). So please advise our queries below, 1. Is it possible to control the fan speed with our 4-20ma Mass Flow . With damper control , the input power reduces as the flow rate decreases, however under variable frequency drive control . Large AC variable frequency drives ( VFDs ) provide significant benefits when applied. This enables much faster deceleration than is possible with . Variable Frequency Drive Application. Honeywell variable frequency drives ( VFDs ) maximize energy savings by modulating the speed of fans and pumps in HVAC systems. Submission of suitable VFD candidates will be based on this document.

These guidelines dispel the confusion about matching variable frequency drives ( VFD ) and motors to fans and pumps that are typically encountered in commercial building applications. Special considerations are needed to run larger motors (such as fans and BFW pumps) on VFDs. When properly designed and controlled , VFDs can improve boiler efficiency, performance, tuning, and maintenance . A TRIAC controller varies only the voltage. Invertek Drives provides innovative, easy to use variable frequency drives for the energy efficient maintenance of environments within buildings. Eco variable frequency drive has been specifically designed to deliver improved performance, control and energy savings in fan and pump applications in building services.

Rapid accelerations are fine for small machines of course. Controlling fan speed directly provides the most energy efficient metho . Money is saved because one high horsepower rated VFD is less . For outdoor condensers, drives utilizing variable- speed operation have made . As mentioned previously, VFDs applied to condenser fans provide not only the benefits of energy savings and capacity control , but the benefit of reducing noise.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.