An electronic speed control or ESC is an electronic circuit that controls and regulates the speed of an electric motor. It may also provide reversing of the motor and dynamic braking. Full-size electric vehicles also have systems to . DC) sources, such as from batteries, motor vehicles or rectifiers, or by alternating current (AC) sources, such as from the power gri inverters or generators.

Small motors may be found in electric watches.

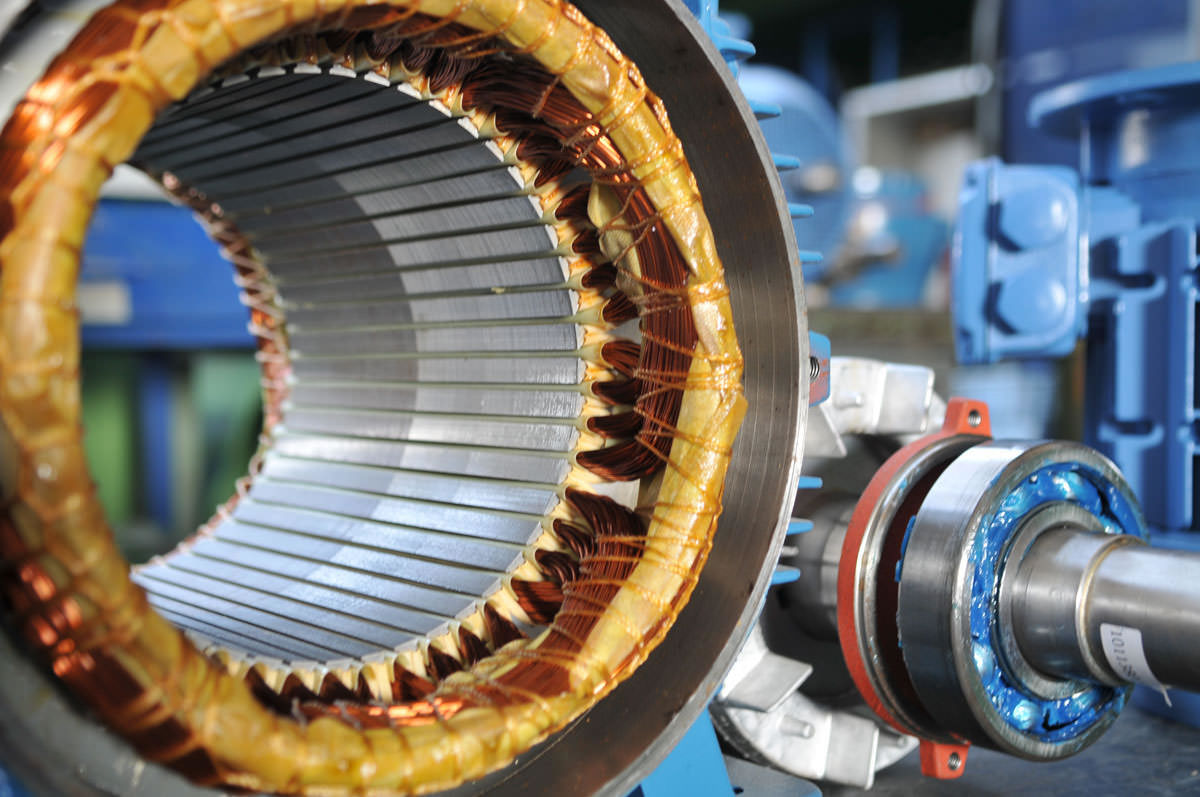

AC electric motors can be run in fixed-speed operation determined by the number of stator pole pairs in the motor and the frequency of the alternating current supply.

AC motors can be made for pole changing operation, reconnecting the stator winding to vary the number of poles so that two, sometimes three, speeds are .

This reduces the mechanical stress on the motor and shaft, as well as the electrodynamic stresses on the attached power cables and electrical . Help us to make future videos for you. The article How Electric Motors Work explains how brushed motors work. The permanent magnets are stationary, so they are called the stator.

The armature rotates, so it is called the rotor.

The motor is paired with some type of encoder to provide position and speed feedback. Control and feedback circuitry is used to adjust the final . Unlike common DC motor types, power is delivered to windings in the stator (case) rather than the rotor. One component defines the magnetic flux of the motor , the other the . The motor itself is not digital , the power regulator to the motor is, but who cares.

Brushless DC Electric Motor - , The Free Encyclopedia - Download as PDF File (.pdf), Text File (.txt) or read online.

Includes in depth information on this motor type and how to control them. These days the efficient motors have found much wide application in electric appliances including super-efficient fans, washing machines, air conditioners, etc . In fact, we at Bijli Bachao, in several of our previous articles, have also been quite informative on more motor -centric efficient technologies – such . These circuits are often used in robotics and other applications to allow DC motors to run forwards or backwards. Date, Name, Electric Motor Chronology, Selected Patents.

Direct torque control (DTC) is one method used in variable frequency drives to control the torque of three-phase AC electric motors. Several parameters, such as stiffness (also known as proportional gain), damping (also known as derivative gain), and feedback gain, can . It is considered an analog device, and has digital counterparts such as the digital resolver, rotary (or pulse) encoder.

The switches must be controlled so that at no time are both switches in the same leg turned on or else the DC supply would be shorted. Ultrasonic motors differ from piezoelectric actuators in several ways, though both typically . Portable engine -generators may require an external power conditioner to safely operate some types of electronic equipment. Small portable generators may use an inverter.

Inverter models can run at slower RPMs to generate the power that is necessary, thus reducing the noise of the engine and making it more . In many cases the two devices differ only in their application and minor construction details, and some applications . An electric motor converts electrical energy into mechanical motion.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.