If neede it can even provide up to five times more, without . At RobotShop, you will find everything about robotics. Brushed DC Motors and other robot products. I am an Applications Engineer at Microchip.

Technology in the Security, Microcontroller and Technology Division.

Help us to make future videos for you.

Any motion control expert should understand the difference between brushed and brushless DC motors to pick the proper motor to optimize your project.

Search for Brush DC Motors Looking for motor solutions? DC motors are high-quality DC motors , equipped with powerful permanent magnets. These motors are typically used where high servo stiffness, fast . In this video we look inside brushed DC motors like the one in our hair dryer.

We can design and build DC motors to exactly meet your requirements. You can achieve energy and cost efficiency by selecting one of our designated solutions for the three main types of brushed DC motors. Brush DC motor technology offers the distinct advantages of low friction, low starting voltages, absence of iron losses, and high efficiency.

Lower the voltage and they slow down.

Reverse the voltage and they go backwards. Description, Price, Supply Voltage, DC Motor Type, Power Rating, Output Spee Shaft Diameter, Maximum Output Torque, Length, Width, Depth, Dimensions, Current Rating, Core Construction, Series, Standards Met . This article covers the factors to take into consideration. So with brushless motors and an ever-increasing array of controls for all motor types, why do engineers still use brush dc motors ? Take command of the speed and direction of your brushed DC motors using these controllers.

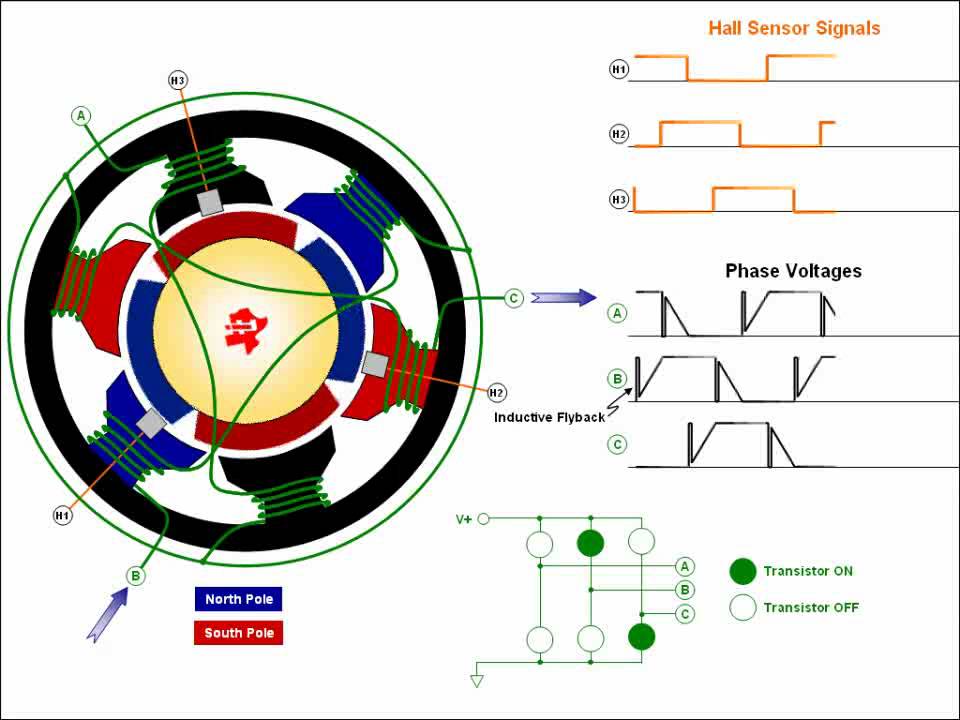

To know the to these questions, we need to know how DC motors operate. The main body of the motor is the stator, consisting of the . MICROMO provides small coreless ( brush ) DC motors from FAULHABER for North America. High Power, compact brushless DC motors for high precision applications. A brushed DC electric motor generating torque from DC power supply by using an internal mechanical commutation.

Stationary permanent magnets form the stator field.

Torque is produced by the principle that any current-carrying conductor placed within an external magnetic field experiences a . When only one direction of rotation is require a single switch topology with PWM modulation can be used to vary the voltage applied to the motor, and thus to control its speed. The article How Electric Motors Work explains how brushed motors work. The permanent magnets are stationary, so they are called the stator.

The armature rotates, so it is called the rotor.

The specific type of motor we are addressing is the permanent magnet brushed DC motor (PMDC). There are two pieces to the motor: 1) stator and 2) rotor . Simple and Economical Motive Power for your Project. Brush DC motor drivers are the most widely used drivers due to their low cost and simple drive control options.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.