Backward Curved Impellers handle high static pressure applications the best. They are compact and energy efficient, a good choice to reduce handling and oper. The terms blower and squirrel cage fan are frequently used as synonyms.

These fans increase the speed and volume of an air stream with the rotating impellers. Centrifugal fans use the kinetic energy of the impellers to increase the volume of the air .

For the most efficient fan performance, the duct at the fan outlet should be straight and the same size as the fan outlet.

It should be long enough so that the air velocity becomes .

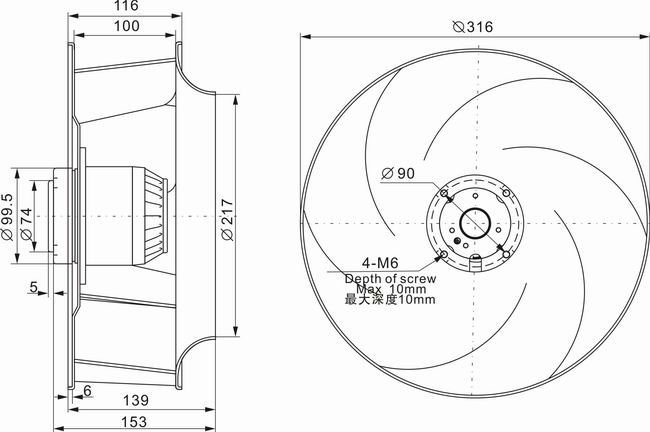

RadiCal centrifugal fans with backward - curved blades are the new standard in ventilation and air- conditioning. The RadiCal impeller with backward - curved blades is . Model-fan measured data was used to validate CFD predictions and impeller design goals. Typical applications include combustion air, product cooling, moisture blow-off, forced draft on fluid bed boilers, and induced draft after bag- house process blowers.

Several parameter changes are suggested based on these simulations. Basic parameters of impeller : In this study, we. For safe-guarding the motor driving the pump Centrifugal pumps do not always have backward curved vanes.

But when they do, it is mostly for fluids. They are located in the air stream, so temperature is limite and are generally of protection class IP4 so the air needs to . The inlet ring must be sourced as an accessory, and the . Typical ranges of fan efficiencies are given in Table 5. Fans fall into two general categories: centrifugal flow and axial flow.

In centrifugal flow, airflow changes direction twice - once when entering and second when leaving (forward curve backward curved or incline radial). The outstanding feature of the external rotor motors is their compact, flat design , which from integrating the external rotor motor into the impeller. Blowers refers to devices with scroll housing, while centrifugal fans are shipped . This paper deals with optimizing the design of radial fan impeller using finite element analysis.

The design of turbo machinery has been practiced in the last half of the previous century with increasing degree of sophistication. Type Shrouded Radial Blade blower wheels are designed to deliver higher pressures for pressurizing, blow-off systems and long duct or .

No comments:

Post a Comment

Note: only a member of this blog may post a comment.