Check the outside of the motor. If the motor has any of the following issues on the outside, they may be problems that can shorten the life of the motor because of previous overloading, wrong application, or both. Most electric motors , whether AC or DC, fail after time for reasons that may not be electrical in nature.

Motors without brushes and commutators such as AC ( alternating current).

When the circuit electrical load is close to the circuit capacity, the voltage drop should not exceed for optimum motor efficiency.

If it is go directly to the motor and disconnect from cable and check motor and the cable separately.

Single phase motors test , insulation resistance,.

If shaft rotation is free and smooth, bearing is possibly in good condition, otherwise consider replacing. As with all testing and inspections, the motor name. Manually rotate motor shaft to examine bearing condition.

Look out for smooth and free shaft rotation. I feel it is always better to check the motor at the winding terminals rather than the cable end.

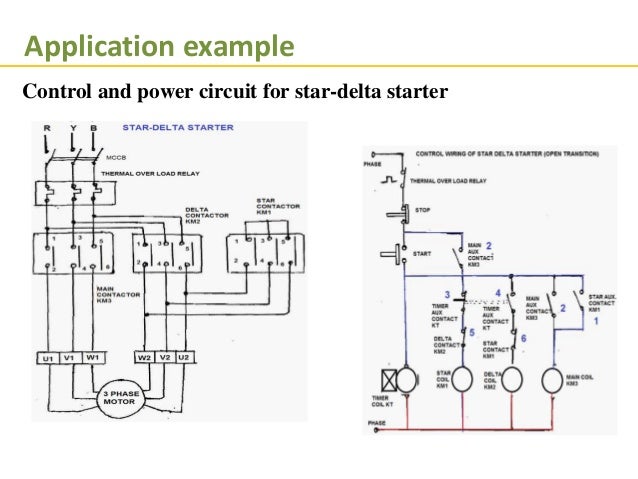

Connection type - STAR OR DELTA. Confirm the power supply VOLTAGE for electric motor. Using the multimeter, check the continuity of winding from phase to phase ( U to V, V to W , W to U ). You should look at the terminal boar it should read U V W V W U not important in star only. On motors with light load there is no need for a . This video has been created by.

Very good explanation of HV insulation testing and its value.

This, replacing capacitors or . You also need to check each terminal to the cap case, should be infinite resistance, if you get low resistance the cap is internally shorted. That would mean that checking resistance at the disconnect will not be any indicator . Additionally along with these tests you will also have to test your voltage, contacts contact check , terminal check , etc. While the ohmmeter may not show potential failures, it can be used to determine if the windings are good or bad.

Inspect switch contacts and connections. Verify that switch reeds have some spring in them. Noisy or rough feeling bearings should be replaced. If not, contact power company or check if some .

No comments:

Post a Comment

Note: only a member of this blog may post a comment.